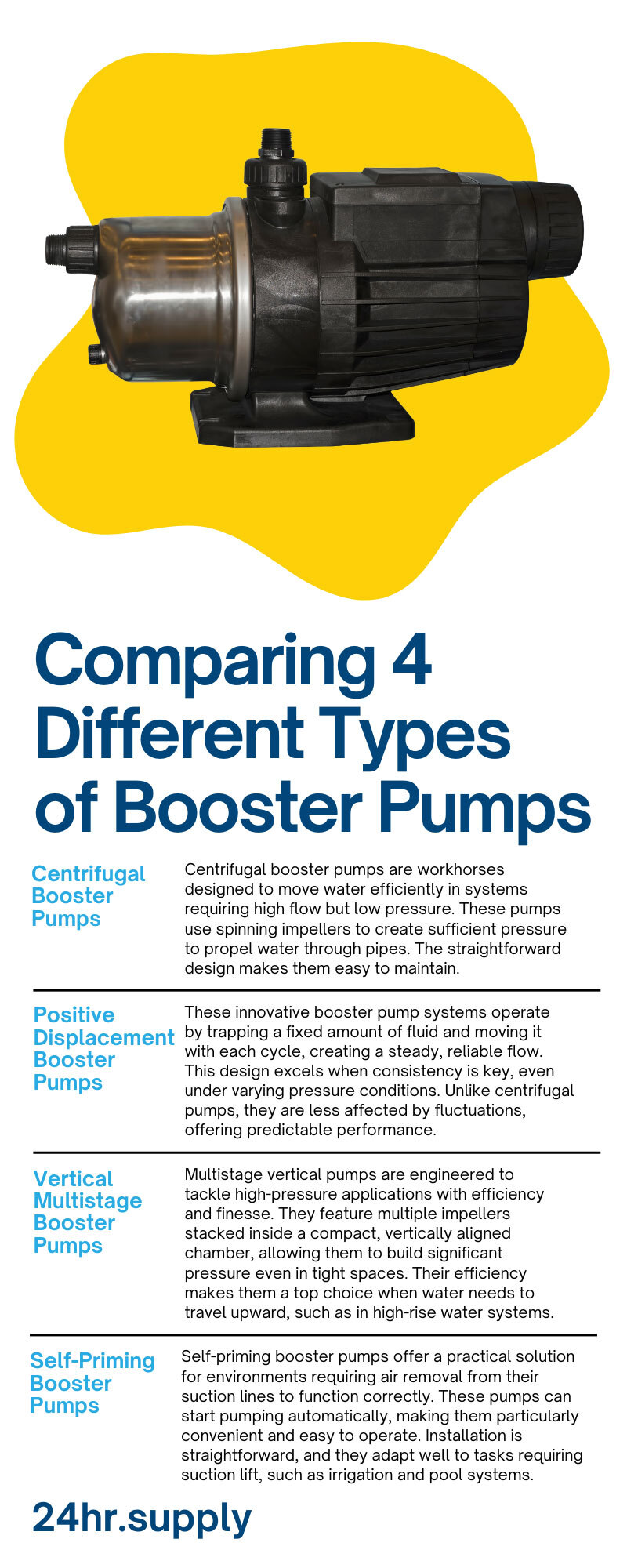

Comparing 4 Different Types of Booster Pumps

When your project demands consistent water pressure or steady flow rates, booster pumps are often the unsung heroes that get the job done. These pumps step in when your regular system can’t quite keep up, delivering the extra push that moves water where it needs to go. Whether you’re working on a high-rise building, an industrial setup, or an irrigation system, choosing the right booster pump makes a world of difference in efficiency and performance.

With so many options out there, it’s important to cut through the noise and figure out what each type of booster pump brings to the table. Some are built for high-pressure applications, while others shine in handling specific types of fluids. Each one has its perks, drawbacks, and a best-fit use case.

This guide compares a few different types of booster pumps and breaks down how they work, what they’re good at, and where they might fall short. By the end of it, you’ll have a clear understanding of your options and how to pick the one that best matches your project’s needs. Let's dig into the details and take the guesswork out of booster pumps.

Looking at Booster Pump Types

First off, let’s talk about which types of booster pumps you’ll see on the market.

Centrifugal Booster Pumps

Centrifugal booster pumps are workhorses designed to move water efficiently in systems requiring high flow but low pressure. These pumps use spinning impellers to create sufficient pressure to propel water through pipes. The straightforward design makes them easy to maintain. Their simple mechanics mean fewer parts to wear out, which helps keep long-term repair costs manageable.

This type of pump shines in applications such as building HVAC systems, irrigation projects, and municipal water systems. They can be a budget-friendly option if you’re moving large volumes of water and don’t need extreme pressure levels. However, projects requiring high-pressure output might need a different solution. Centrifugal pumps struggle to reach their full potential under high-pressure demands, which limits their versatility in certain applications.

Positive Displacement Booster Pumps

These innovative booster pump systems operate by trapping a fixed amount of fluid and moving it with each cycle, creating a steady, reliable flow. This design excels when consistency is key, even under varying pressure conditions. Unlike centrifugal pumps, they are less affected by fluctuations, offering predictable performance.

These pumps are particularly effective when handling viscous fluids or working in specialized environments, like industrial processes or chemical handling. They also stand out in applications where precision and control are critical, making them suitable for delicate or complex operations.

Vertical Multistage Booster Pumps

Multistage vertical pumps are engineered to tackle high-pressure applications with efficiency and finesse. They feature multiple impellers stacked inside a compact, vertically aligned chamber, allowing them to build significant pressure even in tight spaces. Their efficiency makes them a top choice when water needs to travel upward, such as in high-rise water systems.

Space-saving construction means they fit neatly in commercial buildings or facilities where space is limited. Fire protection systems also benefit from their dependable high-pressure capabilities. While these pumps are powerful and efficient, their vertical design can complicate repairs, making it harder to access parts for maintenance.

Self-Priming Booster Pumps

Self-priming booster pumps offer a practical solution for environments requiring air removal from their suction lines to function correctly. These pumps can start pumping automatically, making them particularly convenient and easy to operate. Installation is straightforward, and they adapt well to tasks requiring suction lift, such as irrigation and pool systems.

They perform best when ease of use is a priority, saving time and effort compared to pumps that need manual priming. However, their efficiency typically falls short compared to centrifugal or multistage pumps. While this can be a downside in energy-sensitive applications, they excel in areas like stormwater management, where convenience and adaptability matter most.

Comparing Booster Pumps

Now that you’re familiar with these pump types, let’s compare them side by side across several critical performance factors. What can each one offer?

Performance and Efficiency

Each type of booster pump excels in its own way, catering to unique needs. Centrifugal pumps are designed for high-flow, low-pressure tasks, delivering water quickly and efficiently for large-scale uses like HVAC systems. For precision and reliability, positive displacement pumps are unmatched, maintaining steady flow in fluctuating pressure conditions.

If high-pressure performance is critical, vertical multistage pumps are the go-to, capable of transporting water up tall buildings. Meanwhile, self-priming pumps prioritize ease of use and convenience, ideal for quick setups in irrigation or stormwater applications, though their energy efficiency lags behind the competition.

Application Suitability

The right pump can transform a project. Centrifugal pumps thrive in simple applications such as irrigation and cooling systems. Positive displacement pumps are a staple for managing thick or sensitive fluids in industries like food or chemicals.

Vertical multistage models specialize in high-demand tasks such as high-rise plumbing or fire suppression. Self-priming pumps respond well to portable or fast-paced tasks, such as pool systems or construction sites, offering quick installations and flexible usage.

Cost Analysis

Budgeting depends on your priorities. Centrifugal pumps lead in affordability and require low maintenance, making them great for non-intensive tasks. Meanwhile, positive displacement pumps cost more upfront but deliver precise, reliable flow.

Multistage vertical pump systems balance efficiency and cost, excelling at high-pressure applications. Self-priming pumps provide a cost-effective solution for simpler uses, but their lower efficiency might raise energy costs over time.

Ease of Installation and Maintenance

Pump complexity affects both setup and upkeep. Centrifugal and self-priming pumps are straightforward to install and maintain, ideal for users with limited technical know-how.

Positive displacement pumps are easier to set up but often require diligent maintenance to keep moving parts running smoothly and accurately. Meanwhile, vertical multistage pumps demand expertise for assembly and repairs due to their intricate design.

Durability and Longevity

A pump’s durability depends heavily on its environment. Centrifugal pumps perform well under regular conditions, offering years of steady use. Positive displacement pumps excel in tough settings, enduring abrasive or viscous fluids without issue.

Vertical multistage pumps are built for long-term high-pressure tasks, like skyscraper plumbing. Self-priming pumps, on the other hand, remain versatile but may wear out faster under heavy or continuous use.

Boost Your Pressure Today!

Choosing the ideal booster pump requires you to compare and contrast all of the available options. Think of it like assembling a team of specialists, each excelling in a particular role. The key is knowing what kind of “teammate” your system needs to thrive.

If you’re still unsure which booster pump is your best fit, consider the system’s daily demands, environmental conditions, and long-term goals. Don’t hesitate to consult with professionals who can help guide your choice. A well-chosen pump not only improves performance but also saves time, energy, and resources down the line.

Recent Posts

-

Quick Fixes for a Gurgling Kitchen Sink

A gurgling kitchen sink can be quite a nuisance since it makes such an annoying noise. It usually si …Feb 26th 2026 -

ABS Pipe vs PVC: Choosing the Right Plumbing Solution

ABS pipe vs PVC pipe are two of the most common plastic piping options in plumbing today. ABS (Acryl …Feb 24th 2026 -

What’s the Difference Between PVC and CPVC Pipe?

PVC and CPVC pipes may look similar, but their performance and uses are definitely not the same. PVC …Feb 24th 2026