Noise Reduction Strategies for Urban Booster Pump Installs

In densely populated urban areas, every sound matters. The constant hum of traffic, construction, and daily life creates a complex soundscape where any additional noise can become a significant nuisance. For building managers and residents, the mechanical sounds from essential systems like booster pumps can be particularly disruptive. While these pumps are vital for maintaining consistent water pressure in multi-story buildings, their operation can generate vibrations and noise that travel through structures, affecting comfort and quality of life.

Understanding how to effectively manage and reduce this noise is crucial. Successful noise mitigation not only improves the living and working environment for occupants but also ensures compliance with local noise ordinances, preventing potential complaints and costly modifications. This involves a proactive approach, starting with the design and installation phase all the way through ongoing maintenance. By implementing smart noise reduction strategies for urban booster pump installs, you can make sure your building’s water pressure is strong and reliable without contributing to the city’s noise pollution.

Select the Right Pump for Quiet Operation

The first step in minimizing noise is choosing a booster pump designed for quiet performance. Modern pumps often incorporate features specifically aimed at reducing operational sound. When evaluating the available options, look for models with variable frequency drives (VFDs). VFDs allow the pump to adjust its speed based on real-time water demand, so it only runs as fast as necessary. This prevents the constant high-speed operation that generates excessive noise and also improves energy efficiency.

Also, consider pumps with high-quality, precision-balanced impellers, which reduce vibration and lead to smoother, quieter function. Consulting manufacturer specifications for decibel (dB) ratings will provide a clear benchmark for comparing different models, allowing you to select one that meets your building’s low-noise requirements.

Isolate Pumps From the Building Structure

Even the quietest pumps produce vibrations that can travel through floors, walls, and pipes, amplifying noise throughout the building. To prevent this, you must structurally isolate the pump. Install the pump on a dedicated concrete inertia base, which is a thick, heavy slab that absorbs and dampens vibrations.

Placing vibration isolation pads or spring isolators between the pump’s base and the inertia base adds another critical layer of defense. These specialized mounts are engineered to absorb the mechanical energy from the pump, stopping it from transferring into the building’s structure. This combination of an inertia base and isolators effectively decouples the pump from its surroundings, containing noise at the source.

Choose an Optimal Installation Location

Where you install the booster pump system has a major impact on noise levels. Whenever possible, select a location away from noise-sensitive areas like apartments, bedrooms, conference rooms, and offices. Basements or dedicated mechanical rooms with solid, dense walls made of concrete or masonry are ideal, as these materials are excellent at blocking sound transmission.

Avoid placing pumps in rooms with lightweight construction or near spaces where quiet is a priority. Planning the location carefully during the design phase can prevent the need for complex and expensive soundproofing efforts later on. A well-chosen location acts as the first line of defense in your noise reduction strategy.

Use Flexible Connectors on Piping

Rigid piping acts as a direct pathway for vibrations to travel from the pump into the building’s entire plumbing network. This can cause pipes in distant rooms to rattle and hum. To break this connection, install flexible pipe connectors on both the suction and discharge sides of the pump.

These connectors, typically made of braided stainless steel or rubber, are designed to absorb vibrations and accommodate slight movements. By isolating the pump from the pipework, they stop mechanical noise from spreading throughout the building, ensuring the plumbing system remains quiet. It is a simple but highly effective measure for containing pump-related sounds.

Enclose the Pump in a Soundproof Box

For installations where location options are limited or when an existing pump is too loud, a sound enclosure can provide a powerful solution. Building an acoustic enclosure, or soundproof box, around the pump contains noise directly at the source. To construct an effective enclosure, follow these steps:

- Frame the enclosure: Build a sturdy frame around the pump using metal studs or wood, leaving enough space for maintenance access and proper ventilation to prevent overheating.

- Install acoustic insulation: Line the interior of the frame with high-density sound-absorbing materials like mass-loaded vinyl (MLV) combined with acoustic foam or mineral wool. MLV is excellent for blocking sound, while foam or wool absorbs it.

- Add an exterior layer: Finish the exterior with a dense material like drywall or plywood to complete the barrier. Sealing all joints and gaps with acoustic caulk is crucial to make sure the enclosure is airtight, as even small openings can let sound escape.

An appropriately designed sound enclosure can dramatically reduce perceived noise levels, making it an excellent retrofitting option.

Implement Regular Maintenance Practices

A well-maintained pump runs more efficiently and quietly. Over time, components can wear out, leading to misalignment, rattling, and increased vibration. Establishing a regular maintenance schedule is essential for keeping noise levels in check. This includes inspecting and lubricating bearings to ensure smooth operation, checking the alignment of the motor and pump, and tightening any loose bolts or fittings that could cause rattling.

Worn or damaged parts should be replaced promptly. Consistent maintenance not only helps control noise but also extends the life of the pump and prevents unexpected failures, allowing for reliable water pressure for the building’s occupants.

Your Path to a Quieter Building

Achieving a quiet urban environment requires a careful and deliberate approach to managing mechanical systems. By implementing these noise reduction strategies for your booster pump installations, you can significantly reduce sound and vibration, creating a more comfortable and peaceful setting for all building occupants.

From selecting the right equipment to performing regular maintenance, each step plays a vital role in ensuring your water system operates effectively without adding to the noise. These efforts will not only enhance resident satisfaction but also help you meet regulatory standards, securing your building’s reputation as a well-managed property.

Recent Posts

-

What Causes Pipe Corrosion?

Pipe corrosion occurs when metal reacts with water, oxygen, and minerals over time. Factors that spe …Feb 2nd 2026 -

Commercial vs. Residential Plumbing: 15 Key Differences You Need to Know

Plumbing might seem straightforward at first glance, but residential and commercial systems are fund …Feb 2nd 2026 -

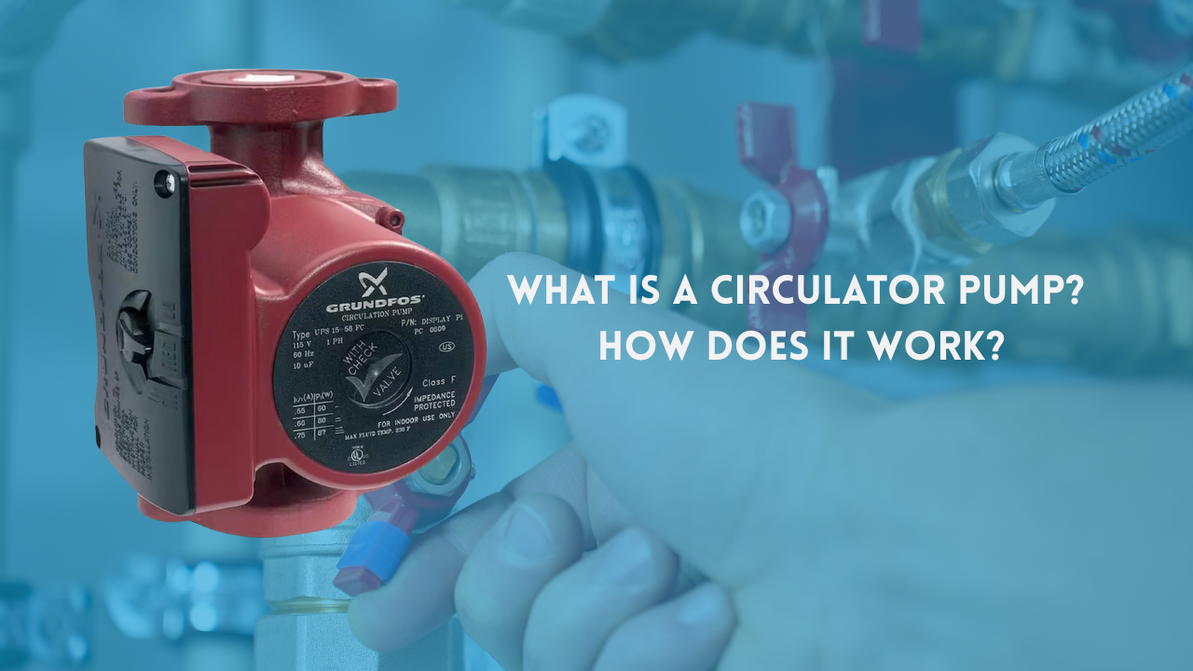

What Is a Circulator Pump and How Does It Work?

Water needs to keep moving efficiently in plumbing and HVAC systems, and that’s where a circulator p …Feb 2nd 2026