What Is a Circulator Pump and How Does It Work?

Water needs to keep moving efficiently in plumbing and HVAC systems, and that’s where a circulator pump comes in. A circulator pump is a device designed to continuously move hot or chilled water through a closed-loop system, ensuring consistent flow, pressure, and temperature.

You’ll commonly find them in hydronic heating systems, domestic hot water loops, commercial HVAC setups, and even solar thermal systems. Read on to discover how circulator pumps function, the different types available, and tips for choosing the right one for your system.

What Is a Circulator Pump?

A circulator pump is a specialized mechanical device designed to move heated water through closed-loop systems, ensuring consistent temperature distribution throughout buildings.

Unlike standard water pumps that move fluid from one location to another, circulator pumps create continuous circulation within existing plumbing networks.

These compact units typically feature a motor-driven impeller housed within a cast iron or stainless steel casing.

The circulator pump for boiler systems operates by creating pressure differentials that overcome friction and resistance in pipes, radiators, and heat exchangers. Most residential units consume between 80-150 watts of electricity and can circulate hundreds of gallons per hour.

Modern circulator pumps incorporate variable speed controls and smart sensors that adjust flow rates based on system demand, significantly improving energy efficiency compared to older constant-speed models.

How Does a Circulator Pump Work?

Let’s now dive into the mechanical process of circulator pumps. This part can get boring but it reveals the elegant simplicity of these essential components.

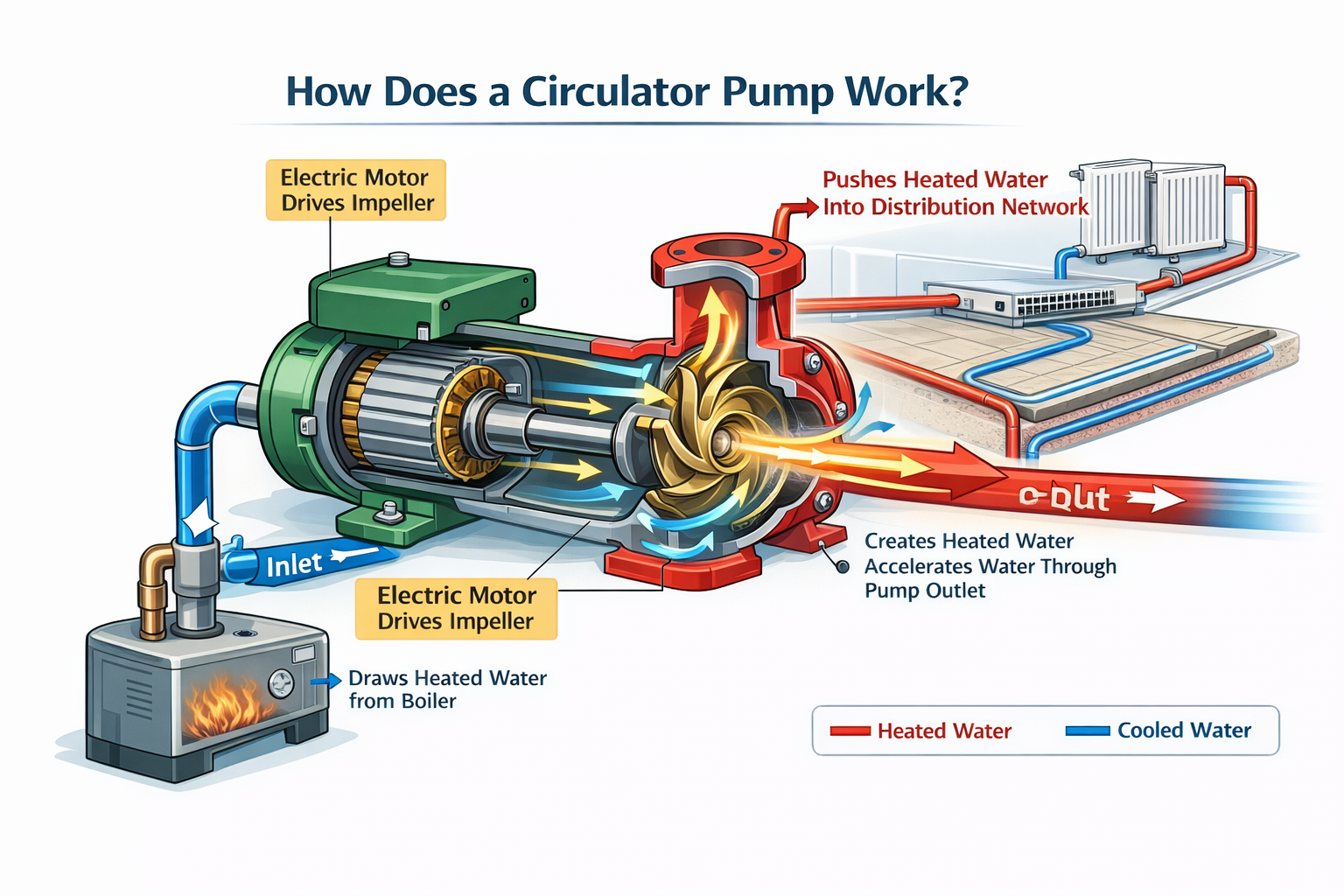

- When your heating system activates, the circulator pump's electric motor drives an impeller, a rotating component with curved blades housed within the pump's volute chamber.

- As the impeller spins, it creates centrifugal force that draws heated water from the boiler through the pump's inlet.

- The spinning motion accelerates the water outward, building pressure that pushes the heated fluid through the distribution network of pipes, radiators, or radiant floor systems throughout your home.

- This continuous circulation ensures that hot water doesn't simply rise and cool water doesn't just sink, instead, the pump maintains consistent flow rates typically ranging from 5 to 50 gallons per minute, depending on system size and requirements.

The process creates a balanced loop where cooled water returns to the boiler for reheating while fresh hot water reaches every zone.

What makes this system particularly efficient? It’s the pump's ability to overcome natural resistance in pipes, fittings, and heat exchangers.

There’s even a variety of pump designs available that ensures optimal performance for different system configurations and household needs.

Types of Circulator Pumps

In the market, there are several distinct circulator pump categories, each engineered for specific applications, and efficiency requirements.

Understanding these variations becomes crucial when planning a circulator pump replacement, as selecting the wrong type can lead to poor performance and increased energy costs.

Wet Rotor Pumps

Wet rotor pumps integrate the motor and impeller in a sealed unit where water lubricates and cools the rotor directly. These compact designs excel in residential applications due to their quiet operation and lower maintenance requirements.

Dry Rotor Pumps

Conversely, dry rotor pumps separate the motor from the fluid using mechanical seals, making them ideal for larger commercial systems where higher flow rates and pressures are essential.

Variable Speed Pumps

Variable speed models is the latest advancement in pump technology. How does it work? It automatically adjusts their output to match system demands. This smart system can reduce energy consumption by up to 50% compared to traditional fixed-speed units, while maintaining optimal comfort levels throughout your building.

Standard Electric Pumps

Standard electric circulator pumps are the most common type used in residential and commercial heating systems. These pumps operate at a fixed speed, often running continuously during heating seasons to maintain consistent water circulation throughout the system.

Most models feature single-speed motors that draw 80 to 200 watts, depending on system size and flow requirements. They typically operate around 1,750 RPM and can move 5 to 20 gallons per minute in residential heating loops.

These pumps are valued for their simplicity, reliability, and ease of installation. Replacement parts are widely available, and maintenance is straightforward.

While they operate at full capacity regardless of actual heating demand, which can increase energy consumption, their durability and low upfront cost make them a popular choice for basic hydronic heating applications.

Variable-Speed Pumps

Variable-speed circulator pumps represent the most advanced category in modern hydronic systems, automatically adjusting their flow rates based on real-time heating demands.

Unlike standard electric models that operate at fixed speeds, these intelligent pumps use electronic controls to modulate performance, delivering precise water circulation whether serving a residential for boiler applications or complex commercial systems.

The technology centers on variable frequency drives (VFDs) that continuously monitor system conditions and adjust pump speed accordingly.

According to federal regulations, these pumps can reduce energy consumption by up to 85% compared to traditional fixed-speed models by eliminating the constant high-energy operation typical of older designs.

What makes variable-speed pumps particularly valuable is their ability to maintain optimal system pressure while responding to changing heat loads, slowing down when fewer heating zones are active and ramping up during peak demand periods.

This piece of tech not only maximizes energy efficiency but also extends equipment lifespan and reduces system noise.

Inline and End-Suction Pumps

Circulator pumps are further categorized by their mounting configuration and suction design. Inline pumps mount directly in the piping system with both inlet and outlet connections on the same axis, making them ideal for retrofit applications where space is limited.

These compact units maintain the pipe's straight-line flow path.

End-suction pumps feature perpendicular inlet, outlet connections, with water entering axially, and exiting radially. This design typically offers higher flow rates and is commonly used as a pump for boiler systems requiring greater capacity.

End-suction models often provide better access for maintenance but require more installation space.

The choice between inline and end-suction configurations depends on available space, flow requirements, and system layout.

Why Circulator Pumps Matter

Circulator pumps serve as the unsung heroes of modern heating and cooling systems, quietly ensuring consistent comfort while dramatically impacting energy consumption.

Dramatic, we know but these compact workhorses circulate heated or chilled water throughout buildings, maintaining uniform temperatures and preventing the hot and cold spots that plague systems with inadequate circulation.

The financial implications are also pretty substantial. According to Regional Technical Forum data, upgrading to high-efficiency circulators can reduce pump energy consumption by 65-85% compared to traditional models.

For commercial buildings, this translates to thousands of dollars in annual savings, while residential users typically see $100-200 reduction in yearly utility costs.

Beyond energy savings, proper circulation extends system lifespan by preventing thermal stress and ensuring even heat distribution. When circulation fails, pump replacement becomes inevitable, often accompanied by costly system damage from overheating or freezing.

This is where the modern variable-speed pumps come in. They adapt automatically to changing conditions, reducing wear while maintaining optimal performance, a critical advantage as systems age and maintenance requirements intensify.

Maintenance and Troubleshooting

Proper maintenance ensures optimal circulator pump performance and extends operational lifespan. Most modern units require minimal intervention, but regular attention to key components prevents costly failures.

Essential maintenance tasks include checking for unusual noise, verifying proper rotation direction, and ensuring adequate lubrication where applicable. Popular brands like circulator pump Taco models often feature maintenance-friendly designs with accessible components and clear diagnostic indicators.

Common Troubleshooting

Common troubleshooting issues involve air entrapment, which causes gurgling sounds and reduced efficiency, and impeller blockages from debris in the system.

However, complex electrical issues or bearing replacement typically require professional service to maintain warranty coverage and ensure safe operation.

Choosing the Right Circulator Pump

Selecting the appropriate water circulator pump requires careful consideration of system specifications and operational demands.

Flow rate, head pressure, and energy efficiency ratings form the foundation of any selection process, with proper sizing being critical for optimal performance.

Variable speed pumps consistently outperform fixed-speed alternatives in most residential applications, offering up to 50% energy savings through automatic flow adjustment.

System compatibility matters equally, ensuring proper pipe sizing, electrical requirements, and mounting configurations prevents costly installation issues down the road.

Professional sizing calculations account for total dynamic head, friction losses, and future expansion possibilities, making expert consultation worthwhile for complex installations.

Key Takeaways for Better System Efficiency

Circulator pumps keep water moving through closed-loop HVAC and hydronic systems to maintain consistent temperatures in residential and commercial buildings.

Unlike transfer pumps, they are designed specifically for continuous circulation within sealed systems, making them ideal for heating, cooling, and hot water recirculation.

Modern circulators offer variable-speed control, energy efficiency, and durable construction for long-term reliability. Proper sizing based on flow rate and head pressure is essential for performance and longevity.

For dependable equipment and fast access to commercial plumbing supplies, emergency plumbing supplies, and a trusted 24 hour plumbing supply, visit 24hr.Supply, your go-to plumbing supply store online and HVAC supply distributor.

FAQs

Can a circulator pump be used for both heating and cooling applications?

Circulator pumps demonstrate remarkable versatility by effectively serving both heating and cooling systems within the same building infrastructure.

Modern circulator pump systems can seamlessly transition between seasonal operations, circulating hot water through radiators during winter months and chilled water through cooling coils during summer periods.

The key to this dual functionality lies in the pump's ability to maintain consistent flow rates regardless of water temperature.

A variable speed circulator automatically adjusts its output to match system demands, whether pushing heated water at 180°F or chilled water at 45°F through the distribution network.

However, system designers must account for different flow requirements between heating and cooling applications. Cooling systems typically require higher flow rates to remove heat effectively, while heating systems often operate efficiently at lower flow rates.

This difference means that while the same pump can serve both functions, proper sizing becomes crucial to ensure optimal performance across both operational modes, setting the stage for understanding the maintenance requirements that keep these versatile systems running smoothly.

What maintenance is required for a circulator pump to ensure optimal performance?

- Regular maintenance ensures circulator pumps operate efficiently throughout their expected lifespan while preventing costly system failures. Most circulator pumps require minimal upkeep, but consistent attention to key components maximizes performance and energy savings.

- Annual inspections should focus on checking for unusual noises, vibrations, or leaks around seals and connections. Clean debris from intake screens and verify proper motor ventilation to prevent overheating. For variable speed circulator pumps, inspect control settings to ensure they're optimized for current system demands.

- Bearing lubrication represents the most critical maintenance task for pumps with serviceable bearings, typically required every 12-18 months depending on operating conditions. However, many modern sealed units eliminate this requirement entirely. Monitor pump performance indicators like flow rates and pressure differentials to identify declining efficiency before major issues develop.

Professional servicing every three to five years helps identify worn impellers, degraded seals, or motor issues that could compromise system reliability and increase energy consumption.

What are the energy efficiency benefits of upgrading to a variable speed circulator pump?

Variable speed circulator pumps deliver substantial energy savings by automatically adjusting their operation to match system demand rather than running at constant speed. Traditional circulator pumps for heating system applications typically consume 80-100 watts continuously, while variable speed models can reduce consumption by up to 85% during partial load conditions.

The key efficiency advantage lies in their ability to modulate flow rates based on real-time heating requirements. When outdoor temperatures are moderate, the pump automatically reduces speed to maintain optimal comfort while minimizing electricity usage.

Most variable speed upgrades pay for themselves within 2-3 years through reduced electricity costs, making them an attractive investment for homeowners seeking long-term savings.

Beyond energy efficiency, these pumps also operate more quietly and extend system component life by reducing mechanical stress during low-demand periods.

How long does it typically take to install a circulator pump in a residential heating system?

Installation time for a circulator pump typically ranges from 2 to 4 hours for a straightforward replacement in most residential heating systems. This timeframe assumes the new pump matches existing connections and requires minimal modifications to the piping system.

Several factors influence installation duration. Simple replacements where the new pump connects directly to existing flanges or unions can be completed in as little as 2 hours. H

owever, installations requiring pipe modifications, electrical work for new wiring, or system draining and refilling may extend to 4-6 hours.

Professional installation is recommended for heating systems, as proper pump sizing, electrical connections, and system balancing are crucial for optimal performance.

DIY installations might take longer due to unfamiliarity with system components and the need for careful attention to proper bleeding procedures.

The complexity increases when upgrading from a single-speed to variable-speed pump, which may require additional electrical controls and system configuration. Weather conditions can also impact installation time, as outdoor work on boiler connections may be needed in some heating configurations.

With proper preparation and the right tools, most residential circulator pump installations are completed within a single service visit, ensuring your heating system returns to full operation quickly.

How do I determine the right size circulator pump for my heating system?

Proper sizing requires calculating your system's flow rate and head pressure requirements. Start by determining the total heat load of your home, typically measured in BTUs per hour, which your HVAC contractor can calculate based on square footage, insulation levels, and climate zone.

The key measurements include flow rate (gallons per minute) and head pressure (feet of water column).

Flow rate depends on your heating system's BTU output, generally requiring 10 gallons per minute for every 100,000 BTUs of heating capacity. Head pressure accounts for resistance from pipes, fittings, and the boiler itself.

Circulator pump selection involves matching these calculated requirements to manufacturer specifications. Variable speed pumps offer flexibility by automatically adjusting to system demands, while fixed-speed pumps must be precisely sized to avoid inefficiency.

What are the signs that a circulator pump needs to be replaced?

- Complete failure to circulate water is the most obvious sign your pump needs replacement. However, several warning signs typically appear before total breakdown occurs.

- Unusual noises like grinding, squealing, and or rattling indicate internal component wear that often can't be economically repaired.

- Reduced heating performance throughout your home suggests the pump isn't moving water effectively through the system. You might notice certain rooms staying cold or radiators that don't heat evenly.

- Visible leaks around the pump housing or connection points indicate seal failure that typically requires pump replacement rather than repair.

Age becomes a factor when pumps exceed 10-15 years of service life. Even if still functioning, older pumps consume significantly more energy than modern high-efficiency models.

Frequent repairs or recurring issues signal it's more cost-effective to replace the entire unit rather than continuing maintenance.

With proper sizing and installation covered, recognizing these replacement indicators helps prevent complete system failure and ensures optimal heating performance.

How do I troubleshoot a circulator pump that is making unusual noises?

- Grinding or scraping sounds typically indicate bearing wear or debris in the impeller housing. Turn off power and check for loose components or foreign objects blocking the impeller.

- Humming without water flow suggests a seized rotor - gently try rotating the motor shaft by hand after powering down.

- Rattling noises often signal loose mounting bolts or pipe vibrations. Secure all connections and ensure proper pipe support near the pump.

- High-pitched squealing usually points to worn bearings that need replacement.

- Cavitation causes a distinctive knocking sound when insufficient water reaches the pump inlet. Check for closed valves, air pockets, or clogged strainers in the system. Water hammer from rapid valve closures creates loud banging - install water hammer arrestors if needed.

Most noise issues stem from improper installation or maintenance neglect. Regular inspection and prompt attention to unusual sounds can prevent costly repairs and extend your circulator pump's operational life significantly.

Recent Posts

-

What Causes Pipe Corrosion?

Pipe corrosion occurs when metal reacts with water, oxygen, and minerals over time. Factors that spe …Feb 2nd 2026 -

Commercial vs. Residential Plumbing: 15 Key Differences You Need to Know

Plumbing might seem straightforward at first glance, but residential and commercial systems are fund …Feb 2nd 2026 -

What Is a Circulator Pump and How Does It Work?

Water needs to keep moving efficiently in plumbing and HVAC systems, and that’s where a circulator p …Feb 2nd 2026