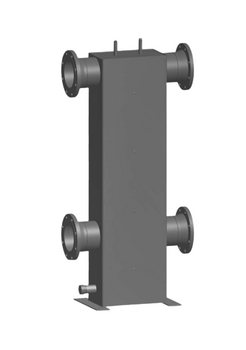

Description

When used in conjunction with the Viessmann boilers, the low-loss header acts as a hydraulic break, decoupling boiler and system circuits from each other. It is recommended to use the low-loss header in applications in which the total system flow rate exceeds the maximum boiler flow rate.

The temperature sensor well located at the top of the low-loss header ensures low return temperatures to the boilers, at all times, increasing operational efficiency. In addition, the low-loss header helps eliminate air and debris from the heating system.

Features

- To decouple high flow rate systems from the boiler loop.

- Enables constant flow through boiler.

- Avoids flow problems in secondary heating circuits.

- Promotes boiler condensation when used with condensing boilers.

- Protect boiler heat exchanger.

- Helps eliminate air, sediment, and debris from the heating system.

- Stand-by losses minimized by highly effective foamed in place or mineral wool insulation (optional accessory).

- Used as a separation point between boiler and system loop for troubleshooting purposes.

When to use a low-loss header:

- When the system flow rate exceeds the maximum boiler flow rate.

- When the boiler flow rate exceeds the maximum system flow rate (usually in multiple boiler systems with a low system.